Workholding is the cornerstone of precision machining, influencing the very essence of accuracy, efficiency, and quality in your operations. At Forkardt Hardinge we are dedicated to the pursuit of precision, setting the gold standard for quality across our product range.

Our commitment to accuracy and quality extends to every facet of our offerings, ensuring that you receive nothing but the best. Collaborate with our expert sales, design, and application engineers to conquer even the most challenging process problems. Alternatively, choose from our trusted selection of standard collets and step chucks, where the Forkardt Hardinge name guarantees uncompromised quality and reliability.

Discover the true value of Forkardt Hardinge Workholding:

Prolonged Product Lifespan: Our workholding solutions are built to last, delivering exceptional longevity.

Increased Machine Uptime: Experience minimal downtime, keeping your operations running smoothly.

Enhanced Work-Piece Accuracy: Achieve precision and consistency in your machining results.

Elevated Customer Satisfaction: Delight your customers with flawless end products.

We take pride in our meticulous approach, lavishing individual care on each workholding device throughout the entire manufacturing process. From the initial handling of bar stock to the final stages of polishing and laser etching, our craftsmanship shines through. With a legacy spanning over a century, Forkardt Hardinge has been at the forefront of manufacturing workholding and industrial products for lathes, mills, and grinding machines. Our deep-rooted process expertise, unwavering precision, and unmatched accuracy have made us a globally renowned name in workholding solutions.

Elevate your machining capabilities with Forkardt Hardinge Workholding and experience a new era of precision and quality in your operations.

Collet Accessories All collet accessories such as wrenches, screws, stops, ejectors, and replacement parts

Equipment These products ensure exceptional accuracy and repeatability, optimizing machining processes and enhancing productivity for a wide array of machining applications.

FNC & FNC+ Chuck Jaws Our precision clamping jaws guarantee secure workpiece fixation during turning, optimizing lathe chuck performance and machine tool productivity. The extensive range includes tailored solutions for diverse machining needs, ensuring maximum efficiency.

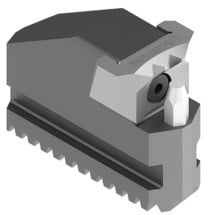

QLC Chuck Jaws Benefit from unparalleled clamping forces with our patented multiple jaw guides. Our backlash-free wedge hook mechanism ensures maximum force and repeatability. Experience superior stability and precision with our extended base jaw profile.

BUCK Chuck Jaws BUCK Chuck Jaws offer a wide range of jaws that include: step, OD grip, inside and outside solid, as well as soft jaw styles to fit any BUCK Chuck.

Shock Absorber

With the new SDVN series, an extremely comprehensive range of versatile shock absorbers for

Tru Change Precision Coupling Ring Low profile, self-centering solution where fast changeover is required. The unique coupling design allows for high torsional loads to be applied to the workpiece, during the process.

English

Français

Deutsch

Italiano

Select your language.

×

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it. Accept No Privacy policy