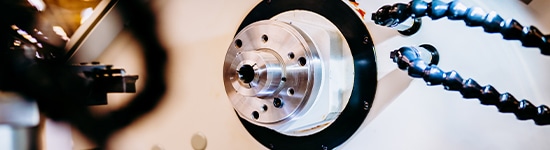

Precision machining demands high-quality workholding solutions to ensure stability, accuracy, and efficiency. Many manufacturers encounter workholding challenges that affect productivity and part quality. Here, we explore common workholding issues and how to address them effectively.

POOR WORKPIECE STABILITY

Challenge:

– Vibration & Chatter – Leads to surface finish defects and premature tool wear.

– Deflection – Thin or long parts may bend under cutting forces, causing inaccuracy.

– Insufficient Clamping Force – Workpieces may shift, resulting in poor dimensional control.

Solution:

– Use precision-engineered chucks and collets for improved rigidity.

– Optimize clamping pressure to balance security and part integrity.

– Consider tailstock support or steady rests for longer parts.

INCORRECT WORKHOLDING SELECTION

Challenge:

– Using Standard Fixtures for Complex Parts – Leads to misalignment and poor repeatability.

– Over-Reliance on Manual Clamping – Inconsistent pressure impacts precision.

– Lack of Modular or Flexible Workholding – Limits adaptability to different part sizes.

Solution:

– Invest in modular and quick-change workholding systems.

– Implement hydraulic or pneumatic clamping for consistent pressure.

– Utilize custom-engineered fixtures for complex geometries.

PART MISALIGNMENT

Challenge:

– Improper Setup – Leads to dimensional inaccuracies.

– Inconsistent Fixturing – Causes variation in production.

– Thermal Expansion Issues – Heat-induced material growth affects positioning.

Solution:

– Ensure precise workpiece positioning with adjustable fixturing.

– Use temperature-controlled machining environments to mitigate expansion issues.

– Regularly inspect and recalibrate fixtures for repeatability.

TOOL ACCESSIBILITY CONSTRAINTS

Challenge:

– Obstructed Toolpaths – Poor fixture design limits full machining access.

– Overhang & Reach Issues – Long tool extensions introduce deflection and chatter.

– Frequent Repositioning – Increases cycle time and error potential.

Solution:

– Design fixtures that allow multi-axis machining without obstruction.

– Minimize tool overhang by optimizing tool length and holder selection.

– Use indexing or rotary workholding solutions to reduce repositioning.

CLAMPING MARKS OR WORKPIECE DAMAGE

Challenge:

– Excessive Clamping Pressure – Can deform softer materials.

– Jaw or Clamp Indentations – Cosmetic or functional defects on finished surfaces.

– Slippage Due to Insufficient Clamping – Causes scrap and rework.

Solution:

– Use soft jaws or customized gripping surfaces to minimize damage.

– Apply controlled clamping force with hydraulic or pneumatic systems.

– Optimize jaw material and contact surfaces for delicate parts.

WORKHOLDING WEAR & MAINTENANCE ISSUES

Challenge:

– Fixture Wear Over Time – Reduces repeatability and precision.

– Contamination (Coolant, Chips, Dirt) – Affects clamping force and alignment.

– Hydraulic or Pneumatic Fixture Failures – Leads to unplanned production downtime.

Solution:

– Implement routine maintenance and inspections for workholding components.

– Keep fixtures clean and free from debris to maintain performance.

– Invest in high-quality, wear-resistant materials for long-term reliability.

HIGH SETUP & CHANGEOVER TIME

Challenge:

– Non-Standard Fixtures – Require lengthy setups.

– Poor Standardization – Increases fixture swap time in high-mix, low-volume production.

– Inefficient Quick-Change Systems – Limits productivity in CNC and grinding operations.

Solution:

– Use standardized workholding systems to streamline setup processes.

– Implement quick-change fixtures to reduce downtime between jobs.

– Train operators to optimize setup procedures and minimize transition delays.

COST & SCALABILITY ISSUES

Challenge:

– Expensive Custom Fixtures – Hard to justify for small batch production.

– Lack of Modular Fixturing – Reduces adaptability to new designs.

– Overly Complex Workholding – Increases fixture costs and operator training needs.

Solution:

– Invest in modular, scalable workholding solutions.

– Utilize adaptable fixtures to accommodate various part sizes and designs.

– Balance complexity with functionality to minimize costs while ensuring performance.

Selecting the right workholding solutions is critical to maximizing machining efficiency and part quality. By addressing these common challenges with advanced fixtures, optimized clamping strategies, and modular systems, manufacturers can achieve superior precision and productivity. With over 130 years of combined experience, Forkardt Hardinge offers innovative workholding solutions tailored to meet your specific machining needs—helping you stay ahead in the industry.

CONTACT US TODAY!

– Tag us in a comment on any social media platform

– Call us at: 833-791-9681

– Send RFQs to: sales@forkardthardinge.com

– LIVE CHAT with us at: www.forkardthardinge.com

For reliable, American-made workholding solutions, Forkardt Hardinge is your complete workholding provider. We are the only company that designs, engineers, manufactures, tests, and supports our products in-house.

At Forkardt Hardinge, we don’t just hold workpieces—we hold the future of Workholding!