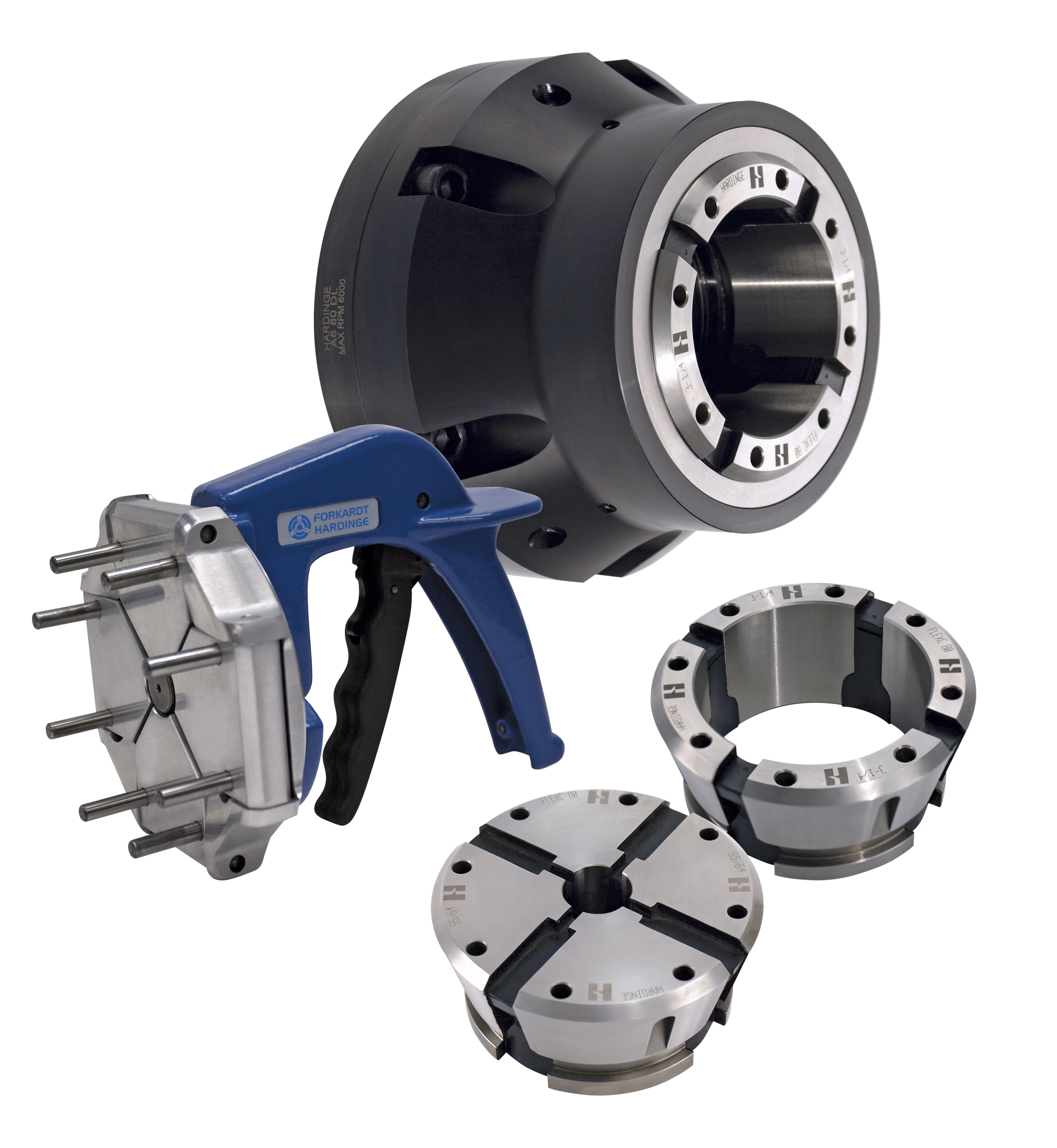

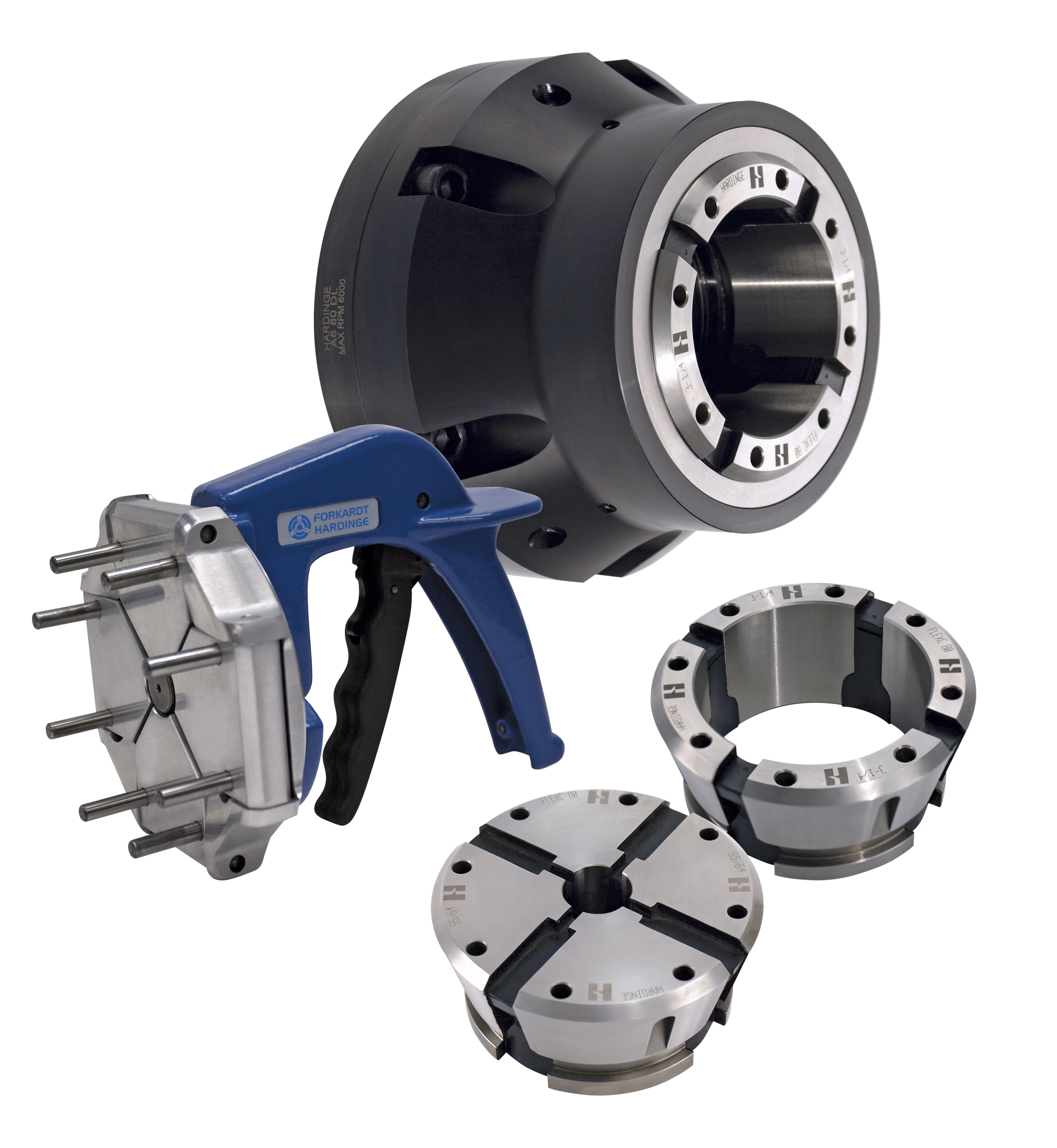

Forkardt Hardinge HCAC Collet Adaptation Chucks will adapt most spindles to accept C-series pull back collets, J-series pull back collets, stationary B-series collets, style-S master collets, step chucks & closers and dead-length collets. It is possible to increase your machining capabilities by substituting a collet chuck over a jaw chuck for part diameters up to 6 inch depending on the spindle size.

The benefits of using collet chucks in place of jaw chucks include:

- Lighter weight, no hoist required to mount on spindle

- Faster job setup time

- Faster acceleration and deceleration due to less weight and smaller diameter

- Higher spindle speeds for reduced cycle times

- Optimum gripping with higher precision capability

- Capable of using master collets and pads

- Improved part concentricity over jaw chucks

- Eliminate time spent on boring jaws

- No hazard of jaws flying off

Another style of Forkardt Hardinge’s collet adapter is their quick-change FlexC Collet System that provides collet changeover in seconds using a manual compression wrench. The FlexC collet system has a guaranteed accuracy within .0004″ (.010mm) TIR for both collet system styles A (pull-back stationary stop) and D (pull-back thru-hole) and .0008″ (.020mm) TIR for style DL (push-to-close dead-length). The collet head has a generous gripping range to allow variation in bar stock without having to change the collet. Because there is no collet body, the collet segments will remain parallel to the stock even when there are variations in the bar stock. This parallel clamping minimizes stock “push back” that could create inconsistent part lengths. The spindle mount will fit on A2-5, A2-6, A2-8 and some flat back spindles (main and sub).

For more information, contact our Customer Service team at 833-791-9681 or visit us 24/7 at www.shophardinge.com to find the right collet system size for your needs.

About Forkardt Hardinge

Forkardt Hardinge has been a premiere global Workholding supplier for over 130 years. The Company’s comprehensive product portfolio enables it to provide solutions in every major industry and region. Forkardt Hardinge’s workforce is composed of dedicated engineers, who are experts across the full spectrum of products including collets, chucks, rotary tables, cylinders and accessories for both standard and engineered solutions.

Forkardt Hardinge’s customer first approach, coupled with industry leading quality and technology, makes the Company an ideal partner for manufacturing solutions. Through continued innovation, Forkardt Hardinge brings advancements in workholding technology that is trusted by small and large machining professionals around the globe.